-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Molding Type | Injection Molding | Product Size | Customized |

|---|---|---|---|

| Application | Automotive | Transportation | By Sea/Air/Express |

| Tolerance | ±0.02mm | Design | Customized |

| Mold Life | 500,000-1,000,000 Shots | Package | Carton/Wooden Case |

Product Description:

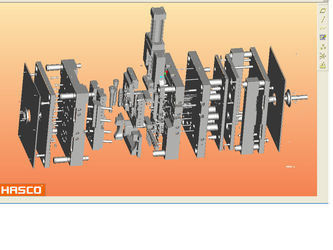

Automotive Injection Molding is a production process for the manufacturing of automotive parts and components. It is an efficient way to produce parts with high accuracy and precision. It is an ideal option for the production of vehicle parts that require complex shapes and tight tolerances. The injection molding process involves the use of a mold and specialized machinery to inject molten material into the mold. The mold is designed to create the desired shape and size of the product. The molten material is cooled and then ejected from the mold. The end product is then ready for assembly or further processing. Automotive Injection Molding offers a number of advantages, including short lead times, low tooling costs, and high-quality and repeatable parts. It is also possible to transport Automotive Injection Molding products by sea, air, or express, making it a cost-effective and efficient option for vehicle injection molding production. Automotive Injection Molding has a long mold life, ranging from 500,000 to 1,000,000 shots. The color and product size of Automotive Injection Molding can be customized to meet specific requirements.

Features:

- Product Name: Automotive Injection Molding

- Lead Time: 15-30 Days

- Application: Automotive

- Product Size: Customized

- Design: Customized

- Surface Finish: Smooth

Technical Parameters:

| Attribute | Value |

|---|---|

| Design | Customized |

| Cavity | Multi-Cavity |

| Material | Plastic |

| Surface Finish | Smooth |

| Lead Time | 15-30 Days |

| Tolerance | ±0.02mm |

| Transportation | By Sea/Air/Express |

| Product Size | Customized |

| Mold Life | 500,000-1,000,000 Shots |

| Package | Carton/Wooden Case |

Applications:

Automotive injection molding is widely used for producing vehicle parts such as bumpers, door panels, interior trim, plastic grille, window frames, and many other automotive components. The automotive injection molding process is optimized to produce parts that have a high level of accuracy, reliability, and custom design. Automotive molds can be customized to generate multiple cavities and various product sizes. The mold life is exceptionally long, lasting up to 500,000 to 1,000,000 shots. The transportation of the parts is also made easier with the option to choose from sea, air, or express. Automotive injection molding is a cost-effective and timely solution to producing high-quality vehicle parts.

Customization:

We specialize in providing custom automotive injection molding services, using premium quality plastic materials and precise injection molding techniques. Our customized injection molding services are suitable for various automotive components, with product size tailored to your specific requirements. All our injection molded parts have a tolerance of ±0.02mm, providing you with the best quality for your automotive parts.

Thanks to our advanced injection molding equipment and experienced molding technicians, we are able to provide the automotive industry with high-precision automotive injection molding services. We are committed to delivering exceptional products and services that meet the highest standards of quality, to ensure the best performance and reliability for your automotive components.

Support and Services:

We provide comprehensive technical support and services for Automotive Injection Molding. Our team of experienced professionals is available to provide support and technical advice, as well as help you troubleshoot any problems you may encounter.

We offer a variety of services, including:

- Design and Engineering Support

- Mold Validation and Testing

- Process Optimization and Troubleshooting

- Maintenance and Repair Services

Our team is also available to provide onsite and remote training, as well as technical support for any questions or issues you may have.

If you have any questions or need any assistance, please contact us. We look forward to helping you get the most out of your Automotive Injection Molding.

Packing and Shipping:

Automotive Injection Molding products are carefully packaged with a protective film to ensure that the product is not damaged during shipping. The product is then placed in a cardboard box and sealed with a tamperproof seal. The box is then marked with the product name, item number, and weight for easy identification. The box is then shipped via a reputable courier service and tracking is provided for the customer.

FAQ:

- Q: What is Automotive Injection Molding?

- A: Automotive Injection Molding is a process used to manufacture mass-produced parts for the automotive industry. It is a highly precise and efficient process that uses specialized plastic injection molding machines to create parts with high accuracy and repeatability.

- Q: What materials can be used for Automotive Injection Molding?

- A: Automotive Injection Molding can be used to produce parts using a variety of thermoplastic materials such as polyurethanes (PUR), polypropylene (PP), polyethylene (PE), and polyvinyl chloride (PVC).

- Q: What are the benefits of Automotive Injection Molding?

- A: Automotive Injection Molding offers several advantages over other manufacturing processes. It produces parts with high precision and repeatability, and it is also an economical and efficient way to produce large quantities of parts.

- Q: What are the drawbacks of Automotive Injection Molding?

- A: Automotive Injection Molding is a highly specialized process that requires a significant investment in equipment and personnel. It also has a relatively high startup cost compared to other manufacturing processes.

- Q: What is the typical lead time for Automotive Injection Molding?

- A: The lead time for Automotive Injection Molding varies greatly depending on the complexity of the part and the quantity of parts being produced. Generally speaking, lead times range from a few weeks to several months.